Troubleshooting Overheating on Your John Deere Excavator: How Coolant Sensors Can Help Prevent Issues

Share

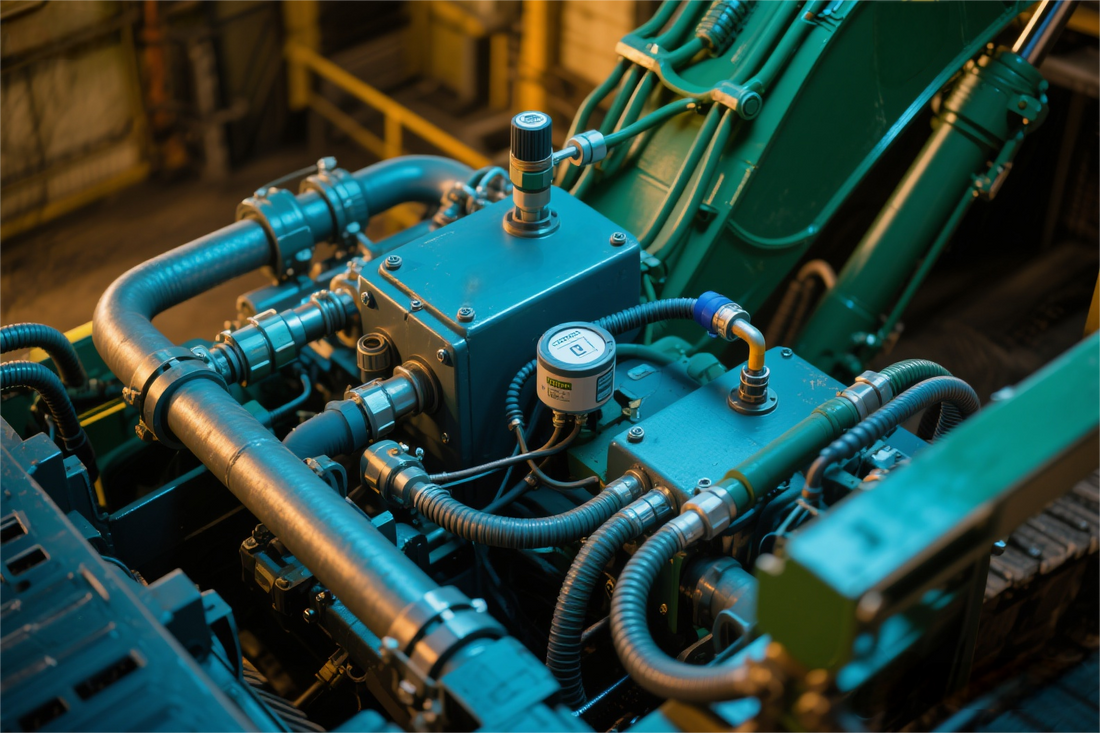

If you’re experiencing overheating in your John Deere Excavator, the problem might lie in the cooling system. Issues like missing thermostats, insufficient coolant drainage, or poor coolant circulation can all contribute to higher engine temperatures. But there’s good news—by integrating coolant temperature sensors and coolant level sensors into your system, you can monitor and manage these issues in real-time, preventing overheating and minimizing the risk of engine damage.

Here’s how to troubleshoot and how your sensors can help ensure your excavator stays cool and performs optimally.

The Case of the Missing Thermostats

One of the first signs that something’s wrong with your cooling system is overheating, and often, this is due to the thermostats failing or being missing. The thermostats regulate the flow of coolant through the engine, ensuring the engine stays at the right temperature. If they fail or are removed, coolant can’t circulate properly, and the engine overheats.

How Our Coolant Temperature Sensors Help:

While fixing or replacing the thermostats is essential, a coolant temperature sensor provides real-time data on the engine's temperature, helping you monitor whether your cooling system is functioning properly. With a temperature sensor installed, you’ll know immediately if the engine temperature is exceeding safe limits, even before the overheating symptoms become critical. This allows you to take action before permanent damage occurs, saving you time and costly repairs.

Tip: If your machine is constantly overheating, and you suspect thermostat issues, the sensor can alert you to temperature fluctuations, prompting a deeper inspection.

Coolant Drain Mystery: Why So Little Fluid?

Another common issue when working on the cooling system is draining coolant from the radiator. Sometimes, when draining, you might notice that not enough coolant is coming out, even though the radiator is large. This could be due to air pockets, incomplete drainage, or trapped coolant in other parts of the system, like the engine block or water pump.

How Our Coolant Level Sensors Help:

If your system consistently shows low coolant levels, a coolant level sensor can help track the fluid levels in real time, alerting you when the coolant is below safe levels or when it’s not circulating properly. This sensor will monitor the coolant in the radiator and engine, giving you an accurate picture of the coolant's movement and volume, so you can quickly identify if a section of the system is not draining properly.

Pro Tip: If you’re not sure if your radiator or engine block has residual coolant, a coolant level sensor can ensure that coolant is always at the correct level and help detect leaks before they lead to bigger problems.

Coolant Capacity: How Much Should Be in the System?

Every excavator has a specific coolant capacity, and it's essential to ensure your machine has the right amount. If your coolant drain leaves you with less fluid than expected, there might be coolant trapped in the engine or hoses, or you could be dealing with leaks or evaporation.

How Our Sensors Help:

Both the coolant temperature sensor and the coolant level sensor work together to ensure your machine is running at peak efficiency. By monitoring the coolant level, the coolant temperature sensor provides crucial feedback about the system's overall health. If the coolant level sensor detects a drop in coolant levels or an abnormal temperature rise, it can send an alert before the problem becomes more serious, saving your engine from overheating and the potential damage that can come with it.

Why Regular Monitoring with Coolant Sensors is Essential

Even if you're able to replace thermostats and drain coolant, there’s a better way to protect your excavator’s engine: proactive monitoring. By integrating our coolant temperature sensors and coolant level sensors, you’ll be able to:

-

Catch problems early: Both sensors provide early warnings for temperature spikes and low coolant levels, which means you can address issues before they lead to expensive repairs.

-

Optimize cooling performance: Continuous monitoring helps ensure that coolant levels and temperatures stay within the ideal range for your machine's performance, ensuring a longer lifespan for your engine.

-

Reduce downtime: By avoiding overheating, you reduce the likelihood of sudden breakdowns, keeping your machine running longer and reducing operational downtime.

Summary: Keep Your Excavator Running Cool with Our Sensors

-

Monitor Thermostat and Temperature Issues: If you’re replacing missing or faulty thermostats, our coolant temperature sensors will give you immediate feedback on how well the system is performing after the fix.

-

Ensure Full Coolant Drainage: If you're concerned about improper drainage or trapped coolant, install a coolant level sensor to monitor fluid levels and avoid running the system with low coolant.

-

Prevent Overheating: By actively monitoring both coolant temperature and coolant levels, you can prevent overheating and ensure the engine stays in the optimal operating range.

-

Optimize Performance: With our sensors integrated into your machine, you’ll have peace of mind knowing that your excavator is running efficiently, minimizing the risk of damage and avoiding costly repairs.

Incorporating these sensors into your maintenance routine is an easy and effective way to ensure that your cooling system is functioning as it should. Whether you're dealing with thermostat issues, coolant drain concerns, or just want to keep tabs on your machine’s health, these sensors are a must-have addition to your excavator maintenance toolkit.